Prototyping Solutions

Using rapid prototyping can revolutionize the market by introducing a new product

Recognizing the benefits of low-volume production, it allows for early performance testing, pre-verification, and validation exercises, minimizing potential surprises in the early stages of mass production.

As a result, we are equipped to handle production quantities from tens to thousands or even tens of thousands in our facility.

Jarltech is committed to bringing successful and aesthetically pleasing products to the market at low volumes and reasonable budgets. We offer a complete assembly solution tailored to your needs.

What are the Benefits of Prototyping?

A prototype is the first fully functional representation of a new product design.

It is used for purposes such as demonstrating to investors, conducting user testing, and providing your audience with a tangible product for visualization and interaction.

Prototypes do not meet the same production standards as the final product. They serve as valuable tools for identifying areas for improvement, allowing you to efficiently refine your product and bring it to market.

The path from concept to market is often a long one, filled with hidden challenges and unexpected twists and turns. Developing a rapid prototype of a design can help navigate this journey and provide significant benefits.

Rapid prototyping gives you the opportunity to revolutionize the market with a new product.

Identify and address problems early and cost-effectively

Authentic innovation always carries the risk of failure. However, creating a prototype allows for the rapid elimination of ineffective methods, enabling a focused effort on those that succeed.

Gather more precise requirements

Escalating project costs often result from rework caused by inadequate requirements.

Traditional methods of gathering requirements, like interviews and focus groups, can be insufficient since many people have difficulty conceptualizing a product before seeing it in tangible form.

By creating a functional prototype, you can demonstrate its capabilities and help refine the requirements for the final design.

Comprehend the Issue in Technical Terms

Over time, your understanding of potential challenges becomes more precise. Creating a functional prototype requires addressing both expected and unexpected technical obstacles in the device's design.

You can then incorporate these solutions into a more refined system design as you move toward the final product.

Conflict resolution

Experienced engineers often have differing perspectives on the execution of specific features, resulting in varying opinions that can be difficult to reconcile.

Using rapid prototyping, you can quickly test different iterations of the feature and compare performance to analyze the trade-offs of each approach. This can save time and ensure accurate design decisions.

Securing Financial Backing

Creating a prototype to demonstrate the feasibility of your idea reduces the investment risk for potential funders. Demonstrating a working prototype greatly increases the likelihood of securing funding for your project.

Step1 - Define

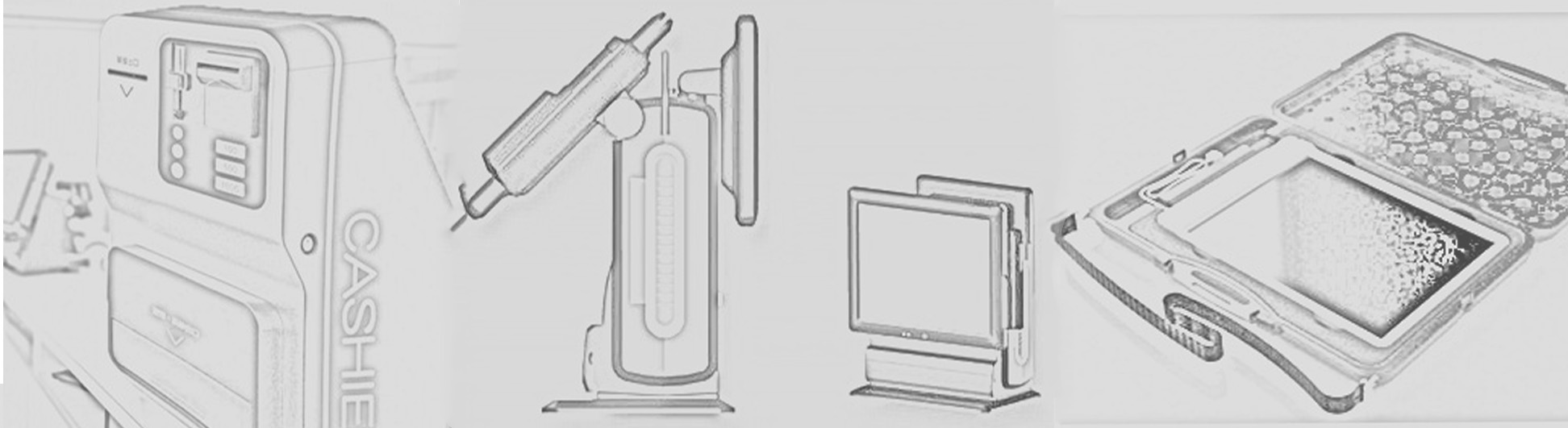

Jarltech prioritizes both performance and aesthetics starting from conceptualization and sketching, to meet and exceed the client's standards and specifications.

At Jarltech, industrial design involves not only designing electronic device enclosures, but also mechanical construction and documentation for mass production.

Step 2 - Ideate

The Jarltech team creates visually appealing product models and seamlessly integrates these conceptual ideas with practical and viable engineering frameworks.

Solutions are encapsulated in rapid 3D CAD models to facilitate feedback from customers, users, and other stakeholders.

Step 3 - Prototype

Using the most effective designs, we create prototype tooling in-house. In a matter of weeks, we can deliver a prototype that looks and functions like the final product.

We can turn abstract concepts into tangible reality by creating mockups. This allows us to test feasibility while keeping confidentiality intact.

Step 4 - Test

Testing serves as the ultimate validation that a prototype is perfectly aligned with the established design intent and criteria. We use the most appropriate methods based on the project requirements, including environmental and structural considerations.

We use both destructive and non-destructive testing methods to evaluate the hardness properties of a product. Upon completion of the prototype, we provide our customers with a comprehensive test report.

Our current goal, as it has been from the beginning, is to create a reliable and exceptionally accurate prototype that can be reliably replicated for short production runs.

Step 5 - Analyze

The prototypes are then delivered to our client for extensive field testing to gather valuable feedback and identify any issues or bugs that may need to be addressed later.

Conclusion

Prototypes provide the visual and tactile experience necessary for your audience to imagine a product's capabilities.

However, it's important to note that a prototype does not function like a final production model and should not be subjected to regular wear and tear.

The prototyping process allows you to evaluate product features, manufacturing techniques, and user experience before full-scale production.

The insights and data gained from prototype testing are critical to the execution and launch of a successful product.

Swift prototyping speeds up the testing, refining, and launching of your product. This approach lets you enhance your project into a user-friendly and intuitive product.

Service

- Conceptual sketching for exploring potential design solutions

- Using 3D CAD models to improve conceptual definition.

- Specifications for components, color, finish, branding, and materials

- Develop distinctive, high-quality product packaging and graphics