Service

Product Development: A Guide to Bringing Your Product to Market

Our company specializes in the creation of bespoke solutions, designed, constructed, and installed with a focus on flexibility and innovation. Our services facilitate the market launch of your idea while reducing costs.

How to transform your idea into reality

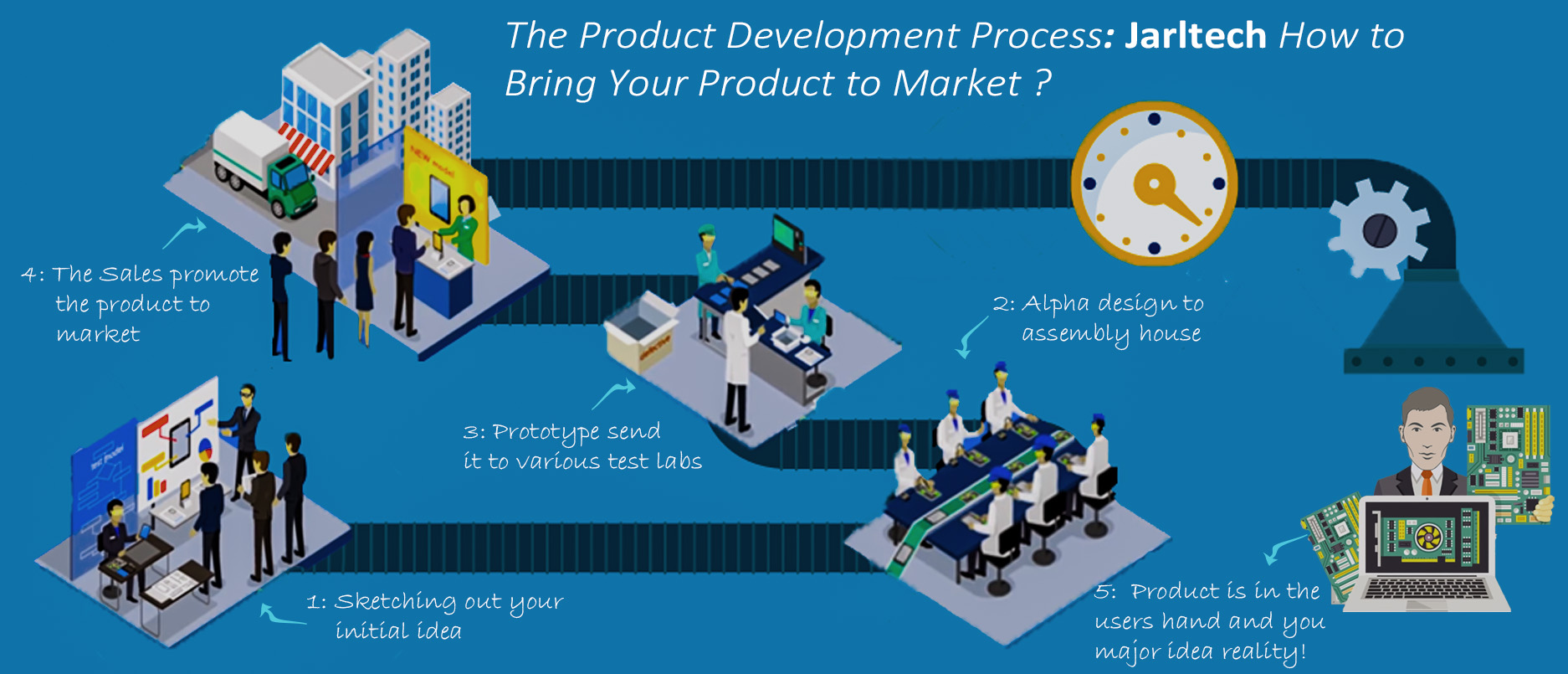

The first step is to create a detailed wish list, with the most important features at the top. Next, begin sketching your initial concept and continue to refine your list. Once you have completed your sketch and identified the necessary functionalities, it is time to collaborate with industrial designers and engineers.

The industrial designers are responsible for the product's aesthetic appeal, tactile quality, and ergonomic design, while the engineers oversee its internal functionality. Both teams will address any queries or concerns you may have regarding your wish list. Once the product's functionality has been established, the designers will begin sketching concepts and planning the case design. Concurrently, the engineers will create a proof of concept using off-the-shelf development kits and pre-made modules. Should any high-risk components be identified, they will be addressed as a priority.

The next step is for the engineers to create a schematic that incorporates all the necessary components to meet the specifications while adhering to the best practices for manufacturing and testing. Once the schematic is finalized, we will proceed to create the alpha PCB layout, which is the first revision of the design that will be built. Alpha boards are typically larger and may include significant changes, as well as additional features like test points and debug headers for troubleshooting. Once the alpha design is complete, the engineers will send the design files to a PCB assembly house for fabrication.

Develop a Prototype

The standard timeframe for this process is two to four weeks, based on the product timeline. However, for an additional fee, we can expedite the process to approximately one week. Upon arrival of the boards, engineers will proceed to power them on and conduct electrical tests by executing test code. Each engineer is provided with a development and testing board, and the design team is also supplied with a board to assess whether any adjustments are required to the enclosure. Once the engineering and design teams have completed the initial development phase and are satisfied with the prototype, they will provide you with a working model. This phase is characterised by close collaboration, with frequent web meetings to make minor adjustments and plan the final design. Once you have approved the new design ideas, the engineers will proceed with their integration.

Following a few rounds of revisions, you now have a fully operational beta prototype. The next step will depend on your product. It may involve sending it to various testing laboratories, with engineers available to guide you through the process. They can also facilitate connections with volume manufacturers for production. Should you intend to place an order in a high volume, you may be required to create a production calibration or test fixture. Your product is now in the hands of users, and your major idea has been brought to fruition.

Bringing a product to market can present a number of challenges and frustrations. It is not a matter of chance or luck. Instead, successful entrepreneurs adhere to principles that have stood the test of time, which help them achieve their goals. Fortunately, these principles can be distilled into specific steps that can be applied to product launch efforts.

By following these steps, you can increase the likelihood of successfully launching a product with confidence and profitability.

Product Development

Product development is a structured process that teams utilize to create new products and enhance...

Electronic Hardware Design

At Jarltech, our research and development teams are committed to designing and developing cutting-edge...

Software Engineering

Jarltech offers comprehensive software design solutions that facilitate the linking of software...

Industrial Manufacturing

Jarltech's research and development teams are dedicated to designing and developing new products...

Quality Management

In today's rapidly evolving market, electronics manufacturers are facing a number of challenges,...

Procurement of Electronic Components

Jarltech provides its own storage and surfing network, which meets customers' immediate needs...