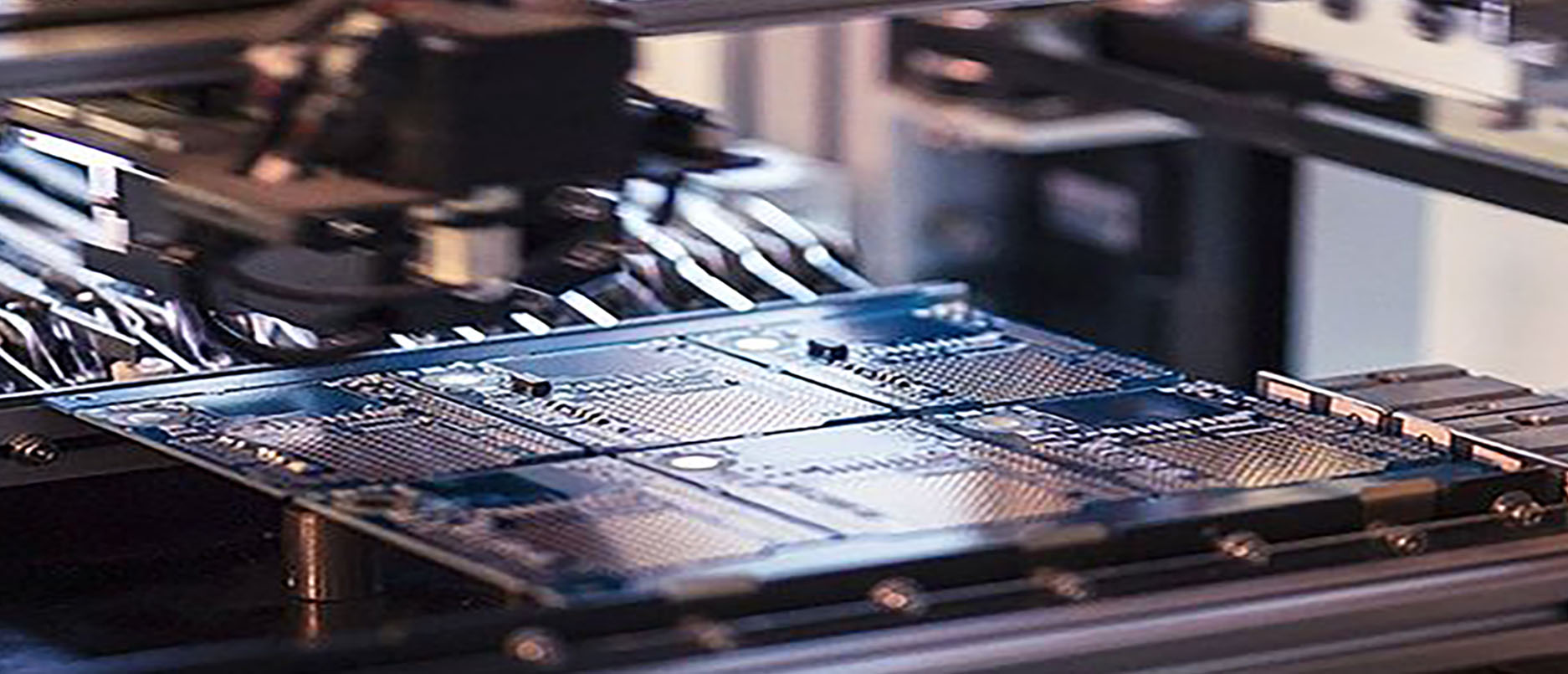

Small Production

The world of product design continues to undergo some fundamental and even revolutionary changes. Product lifespan are getting shorter and so is the expected time to market. How to custom small-production, this is very important topic to all of customers now, Currently, more and more innovation products undergo common customers examine into open their marketing, as a result, many of design company are changing their production to small-production, and ask development time of products will be more quickly.

1. Small-production saves you money

Most people think it’s obvious that manufacturing costs per unit will go down asvolumes go up. By comparison, when a factory is set up for large-scale production itcarries a massive inventory of raw materials and equipment. To cover theirinvestment, they usually ask you to place a large minimum order quantity. But aspecialist in Small-production doesn’t carry the same amount of overheadso we can process orders faster and more economically.

Benefits of Small-production

2. Small-production ensures a faster time to market

The pace of technological change is increasing all the time and with it the constantdemand to innovate. This puts product developers under very real pressure tocreate new designs or modify existing ones and get them distributed as soon aspossible. Being the first to market can be the difference between success and failure.Small-production is the ideal way for you to make enough volume to be sellablewithout creating an unsustainable burden of inventory.

3. Small-production gives you design flexibility

During production, you may find some aspect of the design that you want to modify.Small-production lets you make those changes without greatly impactingthe total order.

4. Small-production an option for bridge production

Another benefit of Small-production is that it provides a way for you toscale up to eventual full-scale production. That’s why it’s sometimes known asbridge production or bridge tooling. As volumes progressively increase, you have anopportunity to streamline best practices to achieve further cost savings whileimproving product quality.

Jarltech are able to provide

- Part development (design, calculation, feasibility, product analysis, …)

- Product assembly (Pilot Run, Pre-test, Post-test)

- Test ( IQC, FQC, PQC, OQC… )

- Packaging (logistics support development…)

- Supply chain (parts production, quality, storage, logistics…)

Quality will be our another consideration for you to help retain your customers. Wewill never sacrifice on quality . We guarantee the quality through different types ofcheck and test. Our Small-production service is for you. It’s great if youneed small quantities on a regular basis or if you want to bridge the gap between theprototyping stage and full-scale production. Get to market faster with our Small-production service. With complete production lines, Jarltech can design, produce,assemble , test and delivery requirement for customers.

- Related Files Download