Product Quality Control

From input to output, we have the most stringent disciplines and document control in order to execute production and quality control process, thereby achieving customer target delivery schedule and beyond quality requirements.

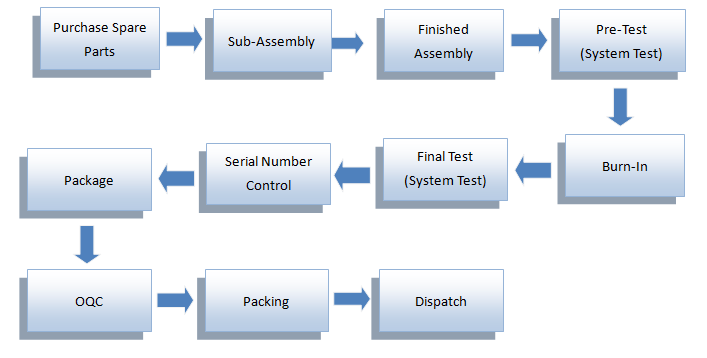

Manufacturing Process Flow Chart

Production Quality Control has distinguished from 3 major parts:

1. IQC (Incoming Quality Control)

Assist Suppliers in quality control of raw material and semi-finished production (module), to handle/control the incoming quality to avoid using the failed components.

Task of IQC:

- IQC Department will ensure the material quality according to the Data Sheet that provided by the R&D Department.

- Follow MIL-STD-105E standard to do Random Inspection.

Inspection Equipment:

- Digital Caliper

- Digital Meter

- ICR Meter

- DC Power Supply

- Cable Tester

- Mechanical Tension Device

- Noise Audiometer

2. In-Process Quality Control

Sub-Assembly and Main Assembly:

- Each process will made follow the SOP, IPQC Department will check and verify each stationaccording to the SOP during the manufacturing process to ensure the production quality.

- During the assembly, import the main material into the Shop-Flow system, record the SerialNumber connection, easy for the Customer to search the Production History.

System Verify:

- Design the different test program and test jigScreen the productions differently by using suitable Test Program and Test Jig with Full FunctionalTest. The production will be maintained if there’s problem detected during this process.

- All the IPC System will execute 2 times of Full Functional Test, Pre-Test before Burn in and Final Testafter Burn in.

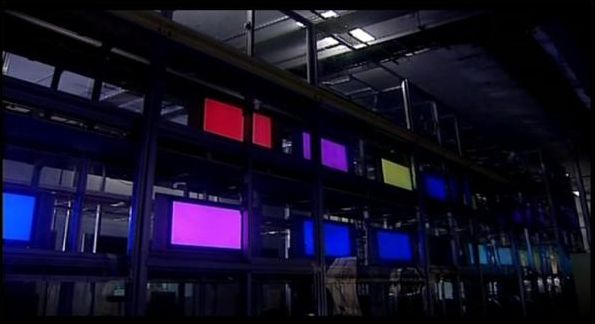

Burn In:

- For the purpose of picking out the fail electronic component, all the IPC system has to run Burn Inprocess by using dynamic test system/program offer continuously full load test.

- The Burn In system at Factory is the automatically Free-Floor, it can control the Burn in timeaccurately by following first-in first out standard, more, it will make the Factory environment looksin order.

- In order to strengthen the Aging Test, we will arrange the random inspection of each lot to run hightemperature turn in test for a long period of time in the ORT Lab.

3.Outgoing Quality Assurance

- Production before been dispatched, our OQC Department will run strictly the essential examine and test following Inspection Specification to make sure the comprehensive of the production.

- Place the finished goods onto the fumigated Wooden Pallet and covered with Water-Proof Bag in order to prevent damp during the transportation.

Quality Control System

Our company has ISO9001, ISO14001 quality system certified and under the strictly Quality Policy, Jarltech International Inc. is more competitive in the market to lead population with technology, satisfied customer with our service, also treat technology skill improvement and company employees training as a long-term investment.