PCB Assembly

We support a complete range of PCB assembly services, including SMT surface mounting, DIP insertion, lead-free processing and hand-soldering. That starting with component mounting through product test processes.

Jarltech's stringent quality practices within flexible, scalable manufacturing infrastructure and various multiple line configurations accommodate high-mix/low-volume, also can execute high volume manufacturing.

Jarltech always work with attention to small details and great customer service, we use our precise SMT equipments and SMT process management, and aim for low cost and quick delivery to satisfy our customers,we show reliability with high quality products and achieve goals through Creative, Precise, and Professional spirit.

Our Assembly Capacity

- 6 Line for SMT

- 2 Line for DIP

- Plant area: approximately 3,600 m²

- Maximum capacity: 50KK point/month (SMT)

- Packaging line x 2

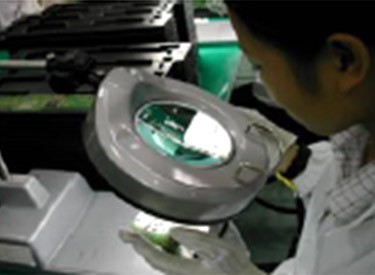

Jarltech's have a fully-equipped in-house inspection system insure the highest quality from incoming raw material through incoming material and quality checks throughout processing.

We ensure our quality assurance system and quality inspection guideline are strictly executed. We put great efforts in staff training and education. We make sure all our new staff has the right skill for their job, and everyone is aware of the importance of quality.

Own Technologies

- AOI (Auto optical inspection).

- 2D/3D Xray.

- Micro-cross section capability.

- BGA Rework Station.

- Programmable Temperature.

- Humidity Chamber.

- COSMO Tester.

- SPI(Solder Paste Inspection).

- SMT Processing

- 6 Lines For Print - High Speed - High Speed - Multi Functional Placement - Reflow

- 6 Lines For Print - High Speed - High Speed - Multi Functional Placement - Reflow

- 6 Lines For Print - High Speed - High Speed - Multi Functional Placement - Reflow

- 6 Lines For Print - High Speed - High Speed - Multi Functional Placement - Reflow

- 6 Lines For Print - High Speed - High Speed - Multi Functional Placement - Reflow

- 6 Lines For Print - High Speed - High Speed - Multi Functional Placement - Reflow

- 6 Lines For Print - High Speed - High Speed - Multi Functional Placement - Reflow

- 6 Lines For Print - High Speed - High Speed - Multi Functional Placement - Reflow

- DIP Insertion Processing

- Inspection and Testing