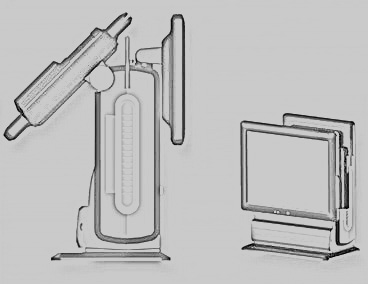

Custom electronic enclosure design

Support for a variety of metal enclosures and industrial print designs

At Jarltech, our research and development teams are dedicated to driving innovation and maintaining the highest standards of design in every new product we create.

We have the capability to integrate customized products from a range of regions, tailored to meet the specific needs of our customers. Whether you have a comprehensive design in place or require guidance in developing a new product, our team is here to support you.

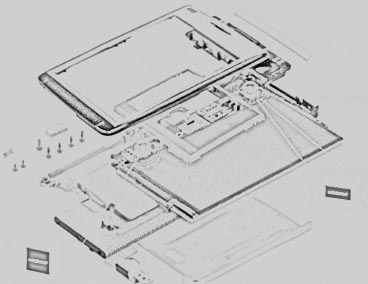

With decades of experience serving the world's leading manufacturers, we cover every aspect of product design and development. Our expertise includes tooling design, plastic injection molding, part assembly and rapid prototyping using a variety of techniques. We provide insight into material selection and manufacturing processes, including machining, die casting, metal and plastic injection molding, and metal stamping. Our comprehensive approach ensures that you have the best options for your project needs.

Industrial Design

Jarltech offers a variety of custom electronic design services tailored to your specific needs. From custom firmware and PCB modifications to metal enclosures and industrial printing, we cover a wide range of design needs. Our full service, from concept to commercialization, helps customers seize market opportunities and leverage our design, manufacturing and marketing expertise to drive growth.

We operate within defined technical and budgetary parameters to ensure a consistent pipeline of opportunities, with the objective of ensuring the success of your product. Our company has extensive experience in product design and engineering across a wide range of industries, projects, materials, and production specifications. Discover how we can assist you in achieving your objectives.

Superiority of Design

At Jarltech, our industrial design services extend beyond enclosure design for electronic devices. We also provide comprehensive mechanical engineering and documentation solutions for mass production. Based on optimal designs, we create prototype tooling in-house, delivering a prototype that accurately reflects the final product within weeks. We transform conceptual ideas into tangible realities by developing mock-ups to assess feasibility while maintaining confidentiality.

Jarltech excels in delivering innovative, comprehensive solutions by deeply understanding the latent needs of our customers. We use creative imagination to develop practical concepts and design intuitive user interfaces for a seamless user experience. By experimenting with new materials and processing techniques, we push beyond traditional boundaries. From initial ideas to production feasibility, we help our clients effectively manage costs within their budgets.

Our services include

• Product definition

• Trend analysis

• Market positioning

• Concept development

We are committed to vertical integration in the electronics industry, ensuring rapid, cost-effective and high quality development and manufacturing. Our experienced engineers are equipped to tackle challenges of any complexity. Once we have determined the optimal design, they will develop a detailed plan to scale the product for production and fulfillment.

Jarltech has the expertise and experience to design both hardware and software to meet your needs. Our team provides innovative ideas and manufacturing efficiencies to improve your product. We offer comprehensive solutions to develop new concepts and refine existing products. From initial concepts and sketches, our design team creates detailed models and presents sustainable design alternatives that balance performance and aesthetics to meet and exceed your standards.

Superiority

- Delivers innovative, comprehensive solutions based on a deep understanding of customers' hidden needs.

- At Jarltech, we employ creative thinking to develop practical and effective concepts.

- Use intuitive user interfaces to improve the user experience.

- We investigate new materials and processing techniques with the objective of exceeding the limits of conventional practice.

- From initial concept to final production, we assist clients in cost management and adherence to budgetary constraints.

Own Technologies

- MCU / DSP / MPU (ARM) based control board design.

- Microcontroller firmware on board update.

- Printer firmware design.

- IP camera firmware design.

- Contact Image Sensor (CIS) firmware design.

- LCM Graphic Display Control.

- LCM Character Display Control.

- VFD Display control.

- Keyboard port programming.

- RS 232 port programming.

- USB port programming.

- AC / DC power management design.

- Magnetic Card Decoder.

- I-Button Key Decoder.

- Smart card chip decoder.

- Small power converter.

- Motor control.

Integrated Application

- Touch Panel.

- Wi-Fi Module.

- Contact Image Sensor (CIS) module.

- TFT LCD Display.

- TFT LCD A/D Board.

- Fingerprint reader.

- 2" & 3" Thermal printer.

- ITX Mother Board for POS.

- Li-ion Battery Power & Charger.

- Lead-Acid Battery Power & Charger.

- Embedded small mother board for POS.

- RFID Module.