Process Flow

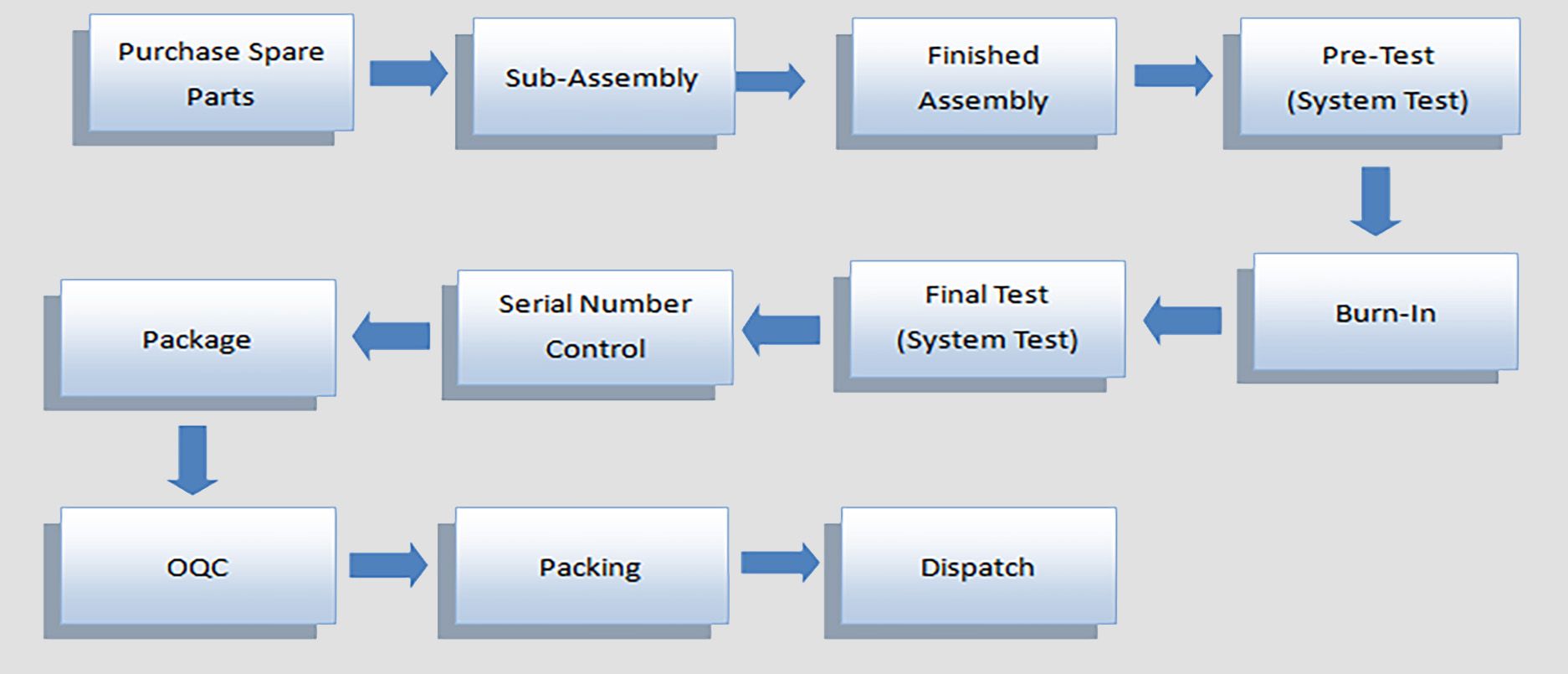

Production Process Flow Diagram

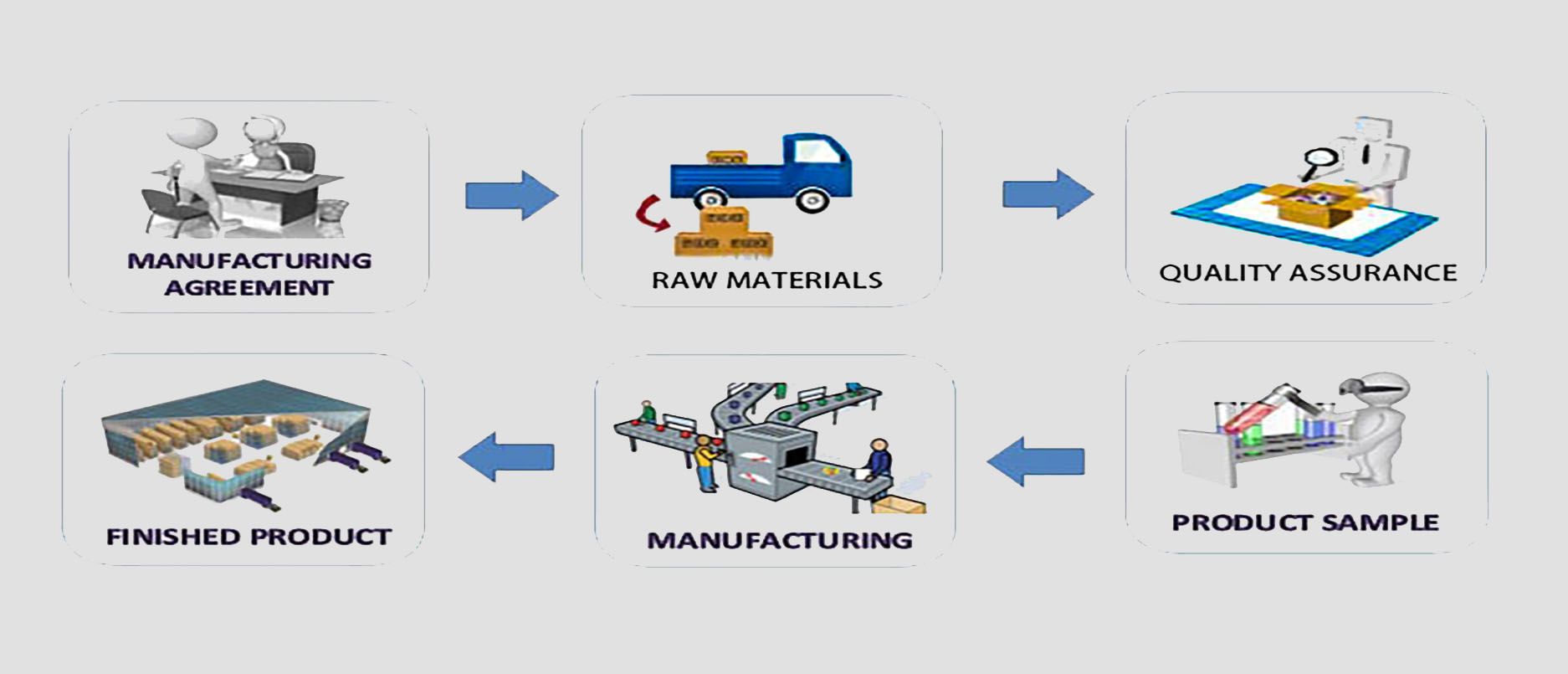

Production Workflow Diagram

Once the sales department has issued a complete order confirmation, the production management team will convert it into a production order and set a process control timetable. The production and quality assurance teams then proceed to execute the plan in accordance with the production schedule, which is monitored at each stage. Subsequent to the quality control inspection, assembly and quality checks are conducted in accordance with the established standards to guarantee operational and production excellence.

To reduce customer wait times for delivery, the production management team will establish annual advanced batch production plans to efficiently manage machine and parts inventory, ensuring optimal stock levels and reducing delivery lead times. **Identification and Traceability of Parts and Machine Information:** Parts and semi-finished products produced in the process are organized according to "5S" principles, with clear labeling of product name, specifications, part number, order number, and current status at their designated locations. This system prevents loss or misplacement of components.

The production inspection process is managed through a "shop floor system," which allows for each item to be individually checked and signed off, ensuring that the machine's historical records are easily traceable. All machine parts are tracked using ERP and other management systems, with comprehensive records of part lists and versions maintained to optimize sales and service efficiency.

Regulations for Site Facilities Management

The maintenance of machinery and equipment used in production is carried out in accordance with the facility and environment maintenance guidelines. This approach helps to prevent disruptions in the production process and after-sales service due to equipment failures.