Headquarters Introduction

Jarltech provides original equipment manufacturer (OEM) and original design manufacturer (ODM) services for electronic products and hardware integration, offering guidance to clients throughout the product development process.

Our factory site is thoughtfully designed, from building materials to interior and exterior layout, with each space serving a specific purpose to benefit both our customers and our team. It houses functions such as sourcing, product management, logistics, administration, marketing, sales, and a manufacturing company - all on one site. Our manufacturing facilities are designed to meet the growing demands of technical innovation and industrial product manufacturing.

1. High-Quality, Custom-Designed Machines

Jarltech is ISO 9001 certified, which provides our customers with the highest level of quality assurance. Our machine specifications are designed to meet the needs of international markets and customer requirements. All machine parts, electronic components, and safety devices comply with CE regulations.

2. Fully equipped SMT/DIP production environment

Our services include component sourcing, SMT, DIP, soldering, assembly, testing, and finished product packaging. We are committed to continuously advancing our automated manufacturing capabilities to deliver a comprehensive, one-stop service that meets our customers' evolving needs. Furthermore, we offer 24-hour SMT and DIP production services. Our flexible production schedule allows us to deliver on time and accommodate small-volume, high-variety production to meet customer ETA requirements.

3. Extensive free-flow assembly line

On Jarltech's Free Flow Assembly Line, various parts and components move through the line, passing through several operators before being assembled into final products for customer use. Typically, in this semi-automated assembly process, the product moves along the line, with each station performing a specific step in production. Workers and machines remain stationary along the line as the product moves through each phase of the cycle from start to finish.

Production Quality Control consists of several key components

• IQC (Incoming Quality Control)

It is essential to provide support to suppliers in the quality control of raw materials and semi-finished products (modules). This will ensure proper handling and management of incoming quality, thus preventing the use of defective components.

Task of IQC

•The IQC department will verify the material quality based on the data sheet provided by the R&D department.

•Perform random inspections in accordance with MIL-STD-105E.

Inspection Equipment

• Digital Caliper

• Digital Meter

• ICR Meter

• DC Power Supply

• Cable Tester

• Mechanical Tension Device

• Noise Audiometer

• In-Process Quality Control

Sub-Assembly and Main Assembly

•All processes will be carried out in accordance with the standard operating procedure (SOP), with the IPQC department inspecting and verifying each station during manufacturing to ensure production quality.

•During the assembly process, the main materials are entered into the Shop-Flow system, along with the corresponding serial number. This allows customers to easily access the production history of their item.

System Verification

•Design and develop a range of test programs and test jigs to assess production quality using the specified test methods. Conduct comprehensive functional testing to ensure product reliability. Any issues identified during this process will be addressed in order to maintain the requisite production quality standards.

•The IPC system will be subjected to two comprehensive functional tests: a preliminary test prior to burn-in and a final test following burn-in.

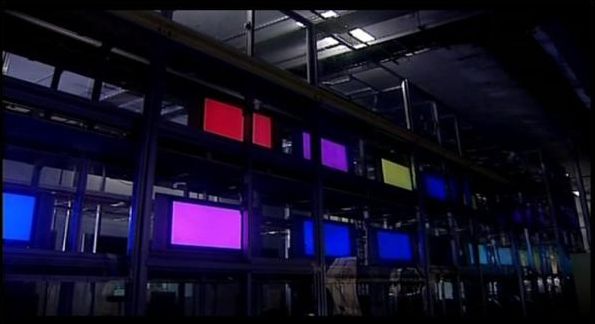

Burn In

•It is essential that all IPC systems undergo a burn-in process using a dynamic test system or program that continuously applies full-load testing in order to identify any faulty electronic components.

•The burn-in system at the factory is an automated, free-floor setup that ensures precise control of burn-in time in accordance with a first-in, first-out standard.

•To enhance the aging test, we will conduct random inspections of each lot and perform extended high temperature turn-in tests in the ORT lab.

Outgoing Quality Assurance

•Before shipment, our OQC department conducts thorough inspections and tests according to the inspection specification to ensure the completeness of production.

•Place the finished goods on fumigated wooden pallets and cover them with waterproof bags to prevent moisture during transport.

4. Fully equipped test facilities

In our product testing, we perform a comprehensive range of tests to ensure that the product meets each customer's specific requirements. Jarltech uses different test equipment for assembly lines, with different test stations designed to perform specific functions. These stations are tailored to the manufacturing process and the customer's needs, ensuring rigorous quality checks to ensure the machine meets the final product specifications.

Furthermore, we provide our customers with warranty and repair services, including ECO upgrades (hardware and software), system-level repairs, and component-level repairs. Each repair project includes a comprehensive engineering failure diagnosis and a detailed root cause analysis. All repair work is conducted in a clean, static-free environment to ensure the highest quality standards are met.

5. Experienced R&D team

Our R&D team is highly skilled in the design and fabrication of custom machines. They are dedicated to enhancing machine quality to meet each client's specific product specifications, weight, and shape for pilot testing. At Jarltech, we are committed to ensuring our clients are fully satisfied with our services.