Surface Mount Technology (SMT)

SMT, its purpose, and surface mount devices, also known as SMDs or SMT components

Jarltech provides superior surface mount technology services, along with offerings in through-hole technology, PCB design, PCB layout, and more.

In this article, we offer a brief introduction to Surface Mount Technology (SMT)

Surface Mount Technology (SMT)

An overview of Surface Mount Technology (SMT), its purpose, and the components involved, known as Surface Mount Devices (SMDs) or SMT components

Take a look inside any commercial electronic device today and you'll find it packed with tiny components.

Instead of using conventional wire-leaded components found in home construction and kits, these parts are soldered to the surface of the board, including a variety of exceptionally small components.

This technology, known as Surface Mount Technology (SMT), is virtually ubiquitous in commercially manufactured devices today. Its widespread use is due to the significant manufacturing advantages it offers: the compact size of SMT components allows a higher density of electronics to be packed into a much smaller space.

In addition to its space-saving advantages, surface mount technology allows for automated production and soldering, resulting in significant improvements in reliability.

What exactly is SMT?

During the 1970s and 1980s, there was an increasing inclination towards automating the construction of electronic equipment. Nonetheless, handling conventional components with leads presented a difficulty.

Resistors and capacitors needed to have their leads pre-formed so they would fit through the holes. In addition, integrated circuits needed their leads to be set at the exact pitch to easily fit through the holes.

In printed circuit board technology, components do not need to have leads that pass through the board. Instead, soldering them directly onto the board is sufficient.

As a result, Surface Mount Technology (SMT) was born, leading to a rapid increase in the use of SMT components as their benefits became apparent and recognized.

Surface Mount Technology (SMT) is the dominant technology in electronics manufacturing today. SMT components can be manufactured in remarkably small sizes, with certain types being used in staggering quantities, particularly capacitors and resistors.

Utilizing Surface Mount Technology (SMT)

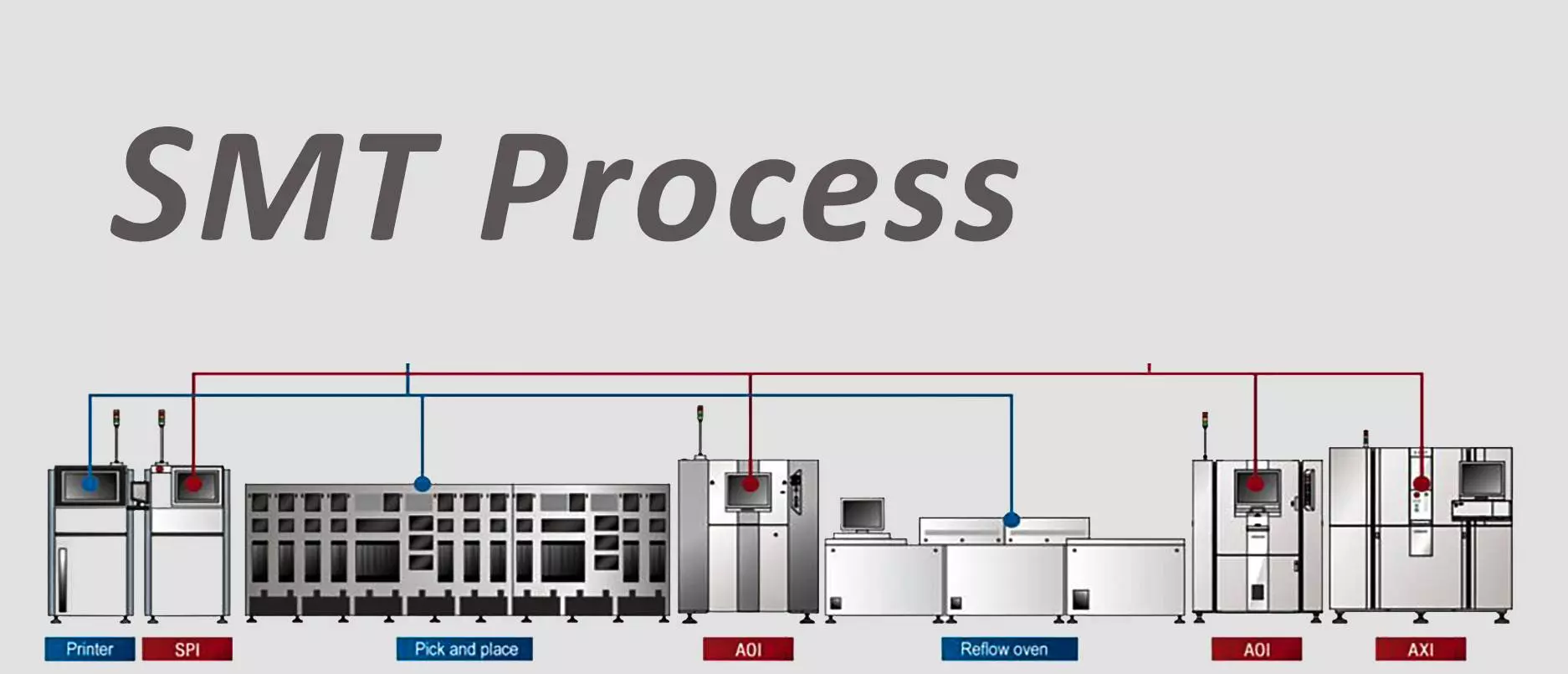

Surface Mount Technology (SMT) is now the most commonly used method for manufacturing electronic circuit boards. This results in smaller boards with improved performance and can be easily integrated with automated pick-and-place machines, greatly reducing the need for manual intervention during assembly.

Automating the placement of wired components has always been a challenge due to the requirement of pre-formed wires fitting into specific holes. However, even with this preparation, placement issues frequently occur.

While some connectors and components may still require manual placement, printed circuit boards are usually designed to minimize this need. In certain cases, the design may even be adjusted to accommodate automated component placement.

In addition, component manufacturers have developed specialized surface-mount versions of components that allow almost complete automated assembly of most boards.

Applications of Surface Mount Technology (SMT)

While it is possible to use certain surface-mount technology components for home construction, it is crucial to exercise caution during soldering. Moreover, soldering even integrated circuits with wider pin spacing can be a difficult task.

Components with fifty or more pins require special soldering equipment and are designed for high-volume production. Even when working on pre-assembled boards, great care is required.

However, SMT components offer significant cost savings to manufacturers, which is why they have become widely adopted. Fortunately for do-it-yourselfers, traditional leaded components, which can be soldered by hand, remain readily available and are often a more suitable option for do-it-yourselfers.

However, SMT components can be used in selected home projects, provided that the leads and connections of the SMT components are of a size that can be handled with more traditional soldering irons and other tools.

Advantage of Surface Mount Technology in Design

• The Design section offers significant benefits, including reduced weight and space requirements, and decreased electrical noise.

• SMT components may weigh just one-tenth as much as their common thru-hole equivalents. This leads to a substantial reduction in the weight of the Surface Mount Assembly (SMA).

• SMT components take up less space, typically one-half to one-third of the space on the board.

• Since not all electronic components are available in surface-mount form, the actual space saved on a board depends on the proportion of through-hole components that are replaced by surface-mount components.

Advantages of Surface Mount Technology in Manufacturing

• There are also significant benefits in the manufacturing sector.

• The significant benefits of using SMT in manufacturing include reduced board costs, reduced material handling costs and a well-regulated manufacturing process.

• Trace routing, board size and the number of drill holes are reduced.

• If the functions on the surface-mount board remain unchanged, the increased inter-package spacing made possible by smaller surface-mount components, together with a reduction in the number of holes drilled, can also lead to a reduction in the number of layers required on the board. This in turn will further reduce the overall cost of the board.

While the benefits of SMT are significant, it's important to note that SMT does not always result in lower costs. The outcome depends on the specific circumstances and methods of SMT implementation.

Disadvantages of Surface-Mount Technology

• Tight lead spaces can be a challenge during repairs.

• It cannot be guaranteed that the solder joints will withstand the compounds used in the potting process. It is uncertain whether the connections will be damaged during thermal cycling.

• Surface Mount Technology (SMT) is not suitable for mounting components that generate high levels of heat or carry heavy electrical loads, as the solder can melt under such conditions.

• Mechanical stress can reduce the strength of the solder. Therefore, components that have direct interaction with a user should be mounted using the robust physical bond of through-hole mounting.

Conclusion

Jarltech offers high quality surface mount technology services together with through-hole technology, PCB design, PCB layout and various other services.

Our highly skilled and qualified PCB layout design team fulfils our customers' custom electronic product development and manufacturing requirements at competitive prices while maintaining a high standard of work quality.

Surface Mount Technology (SMT) | High-Quality Self-Service Kiosk Solutions | Jarltech

Located in Taiwan since 1987, Jarltech International Inc. has been a developer and manufacturer of POS and Kiosk systems for restaurants, retail stores and supermarkets. Their main software and hardware products include, Surface Mount Technology (SMT), small business POS systems, self-service kiosks, smart card readers, Bluetooth thermal printers, embedded motherboards and all-in-one panel PCs, focusing on providing interactive kiosk solutions.

Leverage Jarltech’s 30+ years of expertise in developing innovative POS and Kiosk systems tailored for diverse business needs in restaurants, retail stores, and supermarkets. Our specialized solutions, encompassing IPC, Touch Monitor, Thermal Printer, and Smart Card Reader, are designed to elevate your business operations, ensuring seamless transactions and enhanced customer experiences.

Jarltech has been offering customers global B2B solutions with Jarltech’s POS and Kiosk Systems since 1987, both with advanced technology and 35 years of experience, Jarltech ensures each customer's demands are met.