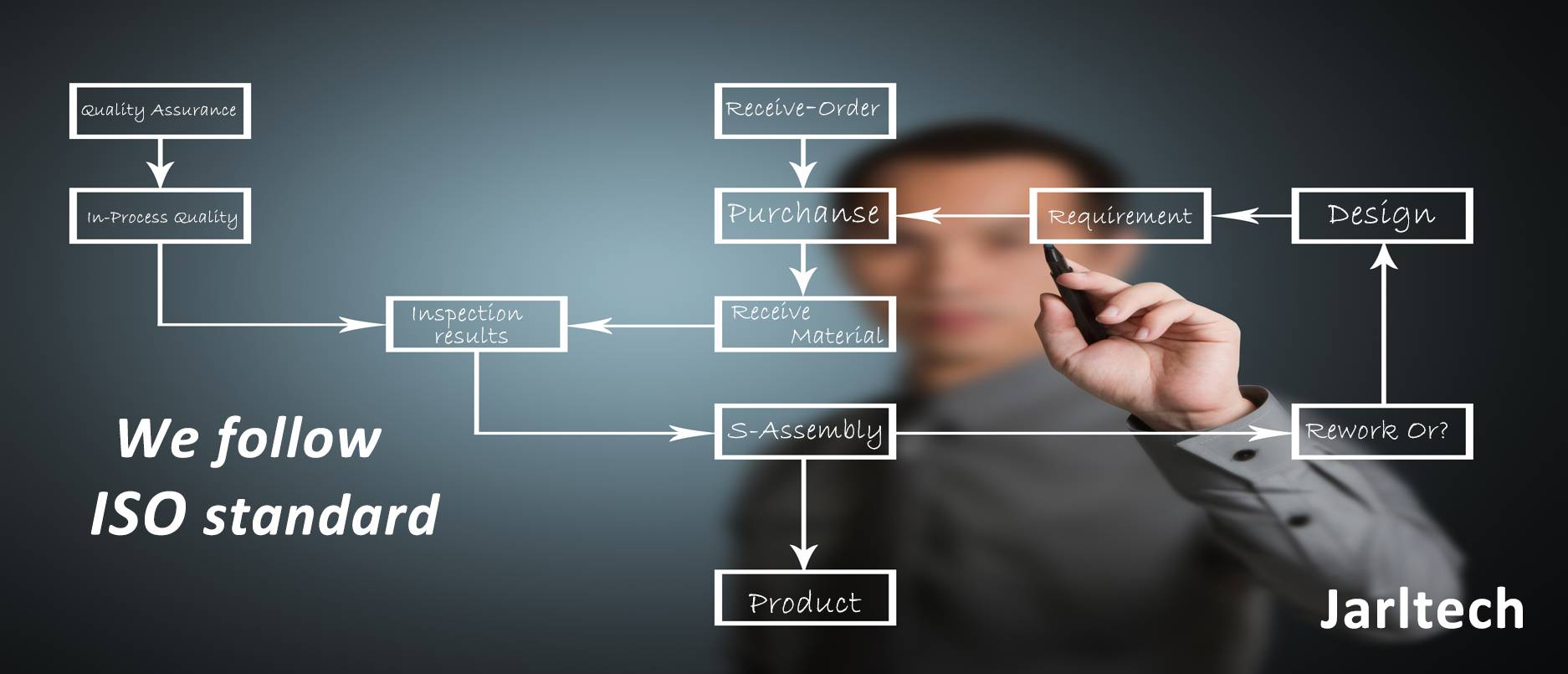

Production Procedures

Compliant with ISO Standards

Production Procedures

A manufacturing process functions as an organic system, featuring dynamic structures with unique properties and rules that differentiate it from its individual components.

Compliant with ISO Standards

Understanding the Manufacturing Production Process

When a manufacturing company begins producing a new material, they can choose which manufacturing process to use.

The process selection depends on factors like the facility, available information systems, and workforce. Each process has unique benefits and may specialize in certain tasks, such as managing sizable quantities of finished goods or creating small amounts of customized items.

Consider key questions when choosing a manufacturing process, including expected production volumes, specific requirements for producing the product, and previous experience with similar products. Has the company previously manufactured a similar product?

Here are some basic manufacturing processes to consider: production line, continuous flow, custom manufacturing, and fixed position manufacturing.

Production Line : A production line is a standard technique typically linked with manufacturing. The product moves sequentially along the line, halting at workstations to execute specific operations.

The item can be moved via a conveyor system or manually with the assistance of staff or a forklift. Tasks along the production line may include assembly, painting, drying, testing, and packaging. If necessary, some components can be removed from the production line and stored as semi-finished goods.

The production line process is ideal for efficiently manufacturing high volumes of either a single product or a group of products.

A production line can be used to manufacture various types of vacuum cleaners. The only difference between the models is the color of the plastic assembly and the attachments included in the final product.

The production line manufacturing process has drawbacks. Its focus on a single or similar products limits its ability to manufacture a wider range of items.

If a vacuum manufacturing company intends to begin producing kitchen mops, they must set up a dedicated production line for the new product, distinct from the one used for vacuums.

The second disadvantage of production lines is the considerable initial expense and requirement for a large quantity of goods to justify the capital investment.

Continuous Flow

The continuous flow manufacturing process is similar to a production line, with one crucial difference : the products must pass through each process in succession without being removed from the production line for storage.

Materials such as chemicals, pharmaceuticals, and plastics are ideal for continuous flow. Nonetheless, the continuous flow process is less adaptable compared to a production line. Modifications for the production of different materials are significant and costly.

Personalized Manufacturing

If a company offers a variety of products that can be customized to meet customer needs, a tailored manufacturing process is the ideal solution.

The manufacturing facility employs skilled workers and uses various tools and machinery to produce and customize a wide range of items.

The facility ought to have assigned areas, which must include a welding section, lathe shop, paint spray area, and packaging zone.

The manufacturing facility is geared towards producing customized products, rather than high-volume manufacturing.

Fixed Position Assembly

Fixed position manufacturing is distinguished from other manufacturing methods by keeping the end product stationary during the entire production process, from inception to completion.

This technique is utilized in the production of large-scale manufacturing, such as in the construction of aircraft or ships. It is also used for products that are assembled onsite for the customer, like conveyor systems.

Electronic Manufacturing Services (EMS) Solutions

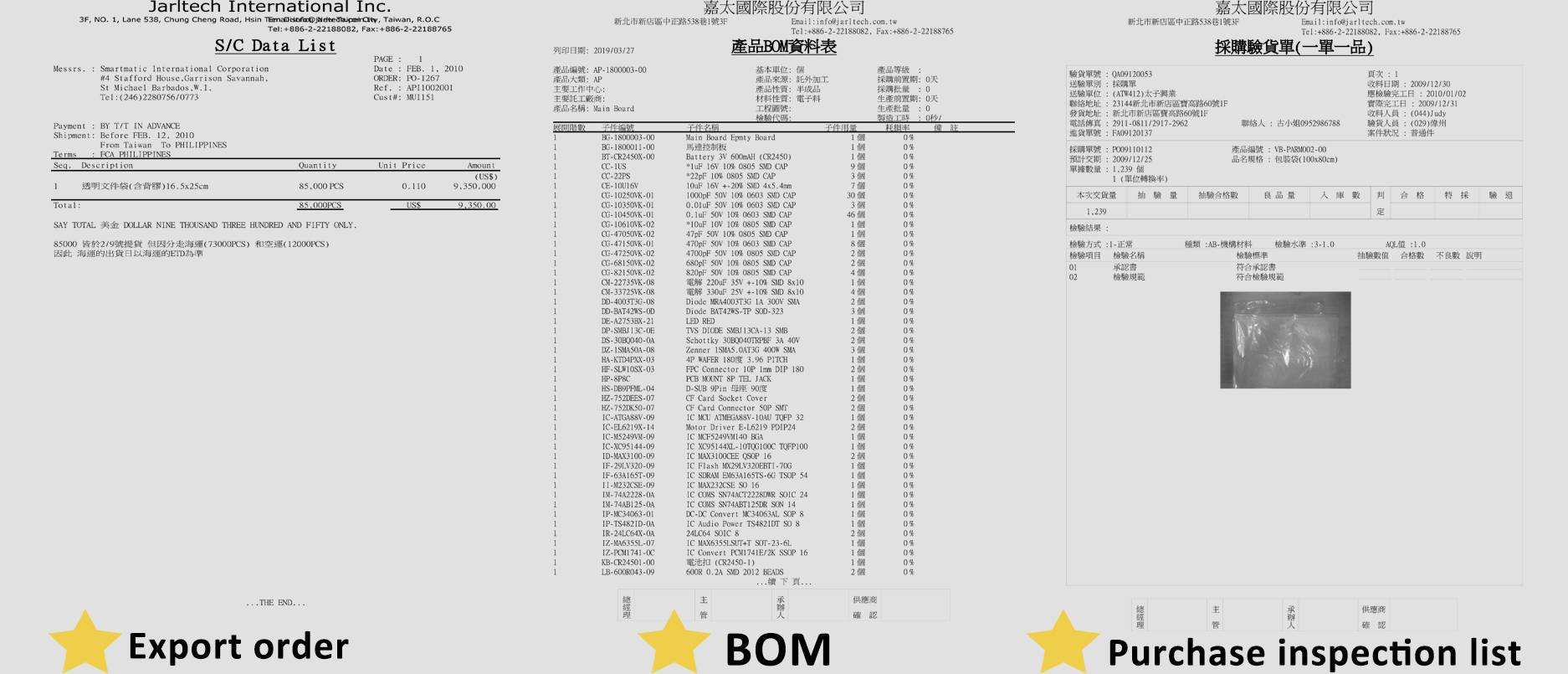

Jarltech provides Electronic Manufacturing Services (EMS) that involve designing, assembling, producing, and testing electronic components and printed circuit board (PCB) assemblies for original equipment manufacturers.

Jarltech provides flexible engagement within the manufacturing process. For example, certain companies may only require a design file from the customer before proceeding with product development.

We help customers source components from our reliable distributor, and provide assembly and testing services. Jarltech ensures consistency in all of our offerings.

We specialize in designing products and offer additional on-site services, such as PCB etching or arranging for these services through our trusted partners.

The amount of automation in electronic manufacturing differs based on the company and project specifications. Companies involved in high-volume production usually utilize comprehensive automation in their manufacturing procedures.

We specialize in creating prototypes or low-volume production runs, and our process involves manual assembly of printed circuit boards (PCBs) to reduce the time and expense of configuring automated assembly equipment.

Production Procedures | High-Quality Self-Service Kiosk Solutions | Jarltech

Located in Taiwan since 1987, Jarltech International Inc. has been a developer and manufacturer of POS and Kiosk systems for restaurants, retail stores and supermarkets. Their main software and hardware products include, Production Procedures, small business POS systems, self-service kiosks, smart card readers, Bluetooth thermal printers, embedded motherboards and all-in-one panel PCs, focusing on providing interactive kiosk solutions.

Leverage Jarltech’s 30+ years of expertise in developing innovative POS and Kiosk systems tailored for diverse business needs in restaurants, retail stores, and supermarkets. Our specialized solutions, encompassing IPC, Touch Monitor, Thermal Printer, and Smart Card Reader, are designed to elevate your business operations, ensuring seamless transactions and enhanced customer experiences.

Jarltech has been offering customers global B2B solutions with Jarltech’s POS and Kiosk Systems since 1987, both with advanced technology and 35 years of experience, Jarltech ensures each customer's demands are met.

.jpg?v=526880a6)